Major Concrete Repairs Incorporating Cathodic Protection and Cathodic Prevention

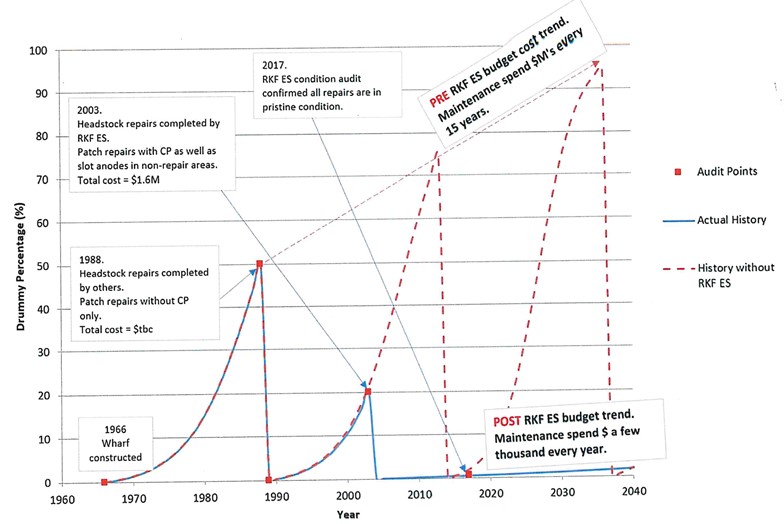

RKF Engineering Services (RKF ES) was engaged by our client, a major Queensland port, to undertake the design of repairs and cathodic protection systems for one of their wharves. Previous repairs were unsuccessful, and the condition of the structure was deteriorating.

RKF ES undertook a full condition survey and option study to determine the most efficient (cost and schedule) method of repairing and maintaining the wharf. Cathodic protection was identified as an essential part of the refurbishment.

The design, installation, QA and commissioning of the concrete repairs and the cathodic protection system was handled by RKF ES.

We managed the repair of damaged sections and the strategic upgrade of the overall facility using precast and cast in situ concrete. The site works involved high pressure demolition, rebar replacement and concrete repair. Detailed structural analysis and a suite of rules allowed major sections of the wharf to be repaired while allowing the facility to continue to load coal. Special purpose high durability, super workable concrete mixes and curing techniques were developed for this job. Cathodic protection systems were integrated within both old and new concrete to ensure the long-term durability of the wharf.

All works were planned out to avoid conflicts with the client’s busy shipping schedule. An ongoing inspection and monitoring strategy was also developed to assist the client manage the concrete piles that were still in adequate condition.

The repairs designed and implemented by RKF ES were commissioned 20 years ago and are still in pristine condition today. In contrast, the previous repairs completed by others using conventional jackhammer and grouting techniques had begun to fail after only 10 years of service.

For further information on this project or in general, send us an email or phone +61 2 4225 7519.